Chapters also address special sheet forming operations like spinning incremental forming and mechanical joining and processes related to sheet forming such as sheet and tube hydroforming roll forming and high velocity forming.

Asm sheet metal forming.

The book also covers the latest developments in sheet metal forming technology including servo drive presses and their applications and advanced cushion systems in mechanical and hydraulic presses.

It describes general principles on how metal forming is accomplished and analyzed when inertial forces are large.

Asm handbook volume 14b metalworking.

This practical and comprehensive reference gives the latest developments on the design of sheet forming operations equipment tooling and process modeling.

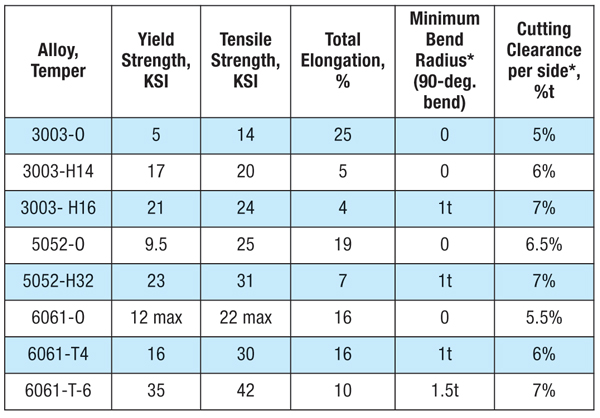

Plastic deformation flow stress anisotropy and formability 5.

Plastic deformation state of stress yield criteria flow rule and hardening rules 6.

Plastic deformation strain and strain rate 4.

Our rapid sheet metal services utilize state of the art software seasoned employees and top of the line equipment to get parts out the door fast and right the first time.

The article discusses the principal methods of high velocity forming such as explosive forming electrohydraulic forming and electromagnetic forming.

It provides examples that illustrate how these methods can be practically applied.

Asm precision inc located in rohnert park california is a precision sheetmetal fabrication company with cnc machining powder coating silk screening.

Sheet forming details this book addresses all methods of sheet metal fabrication technologies selection of equipment and die materials specification of forming practices for specific alloys and new techniques for process design and control.

Materials for sheet forming 7.

This article provides an overview of some of the technologies used for rp and low volume production of sheet metal.

Process modeling using finite element analysis is described in one chapter and discussed in all appropriate chapters.

9 762 9599 fax.

Classification and description of sheet metal forming operations 3.

Topics include stress analysis formability criteria tooling and materials for sheet forming.

Individual chapters cover all major sheet forming processes such as blanking bending deep drawing and more.

Once the sheet metal has been through the laser punching process the resulting blanks often need to be formed into 3d shapes.