The maximum uniformly distributed load w that can be applied over the full length of the beam if the beam is simply supported and has a span of l 23 ft.

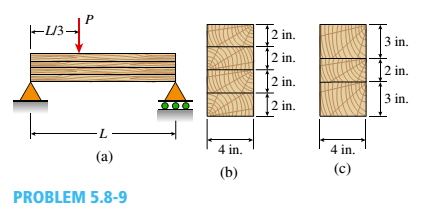

A simply supported laminated wood beam.

Our titan timber beams resist checking and twisting and are job site ready with one piece construction and more cost efficient than lvl and psl.

Planks glued together to form a section 6 in.

Our versa lam lvl is manufactured in either alexandria lena louisiana in eastern united states or in white city oregon for the western united states.

For this reason horizontal holes in glued laminated timbers are limited in size and location to maintain the structural integrity of the beam.

Engineered wood products ewp lvl span and size charts.

Uniformly loaded simply supported beam.

A laminated wood beam consists of eight 2 in.

Wide by 12 in.

Timber technologies glue laminated beams are superior in all strength characteristics to solid sawn lumber and pound for pound stronger than steel.

The tables assume that the original solid sawn or steel beams were designed correctly and are not intended.

The beam carries a 9 kip concentrated load at midspan.

Wide by 16 in.

A 10 ft long simply supported laminated wood beam consists of eight 1 5 in.

Glue laminated glulam beams.

Rosboro x beam glulam superior ered wood s rosboro x beam glulam superior ered wood s wood beam calculator 8 vine calculators 1937 1970 s inland steel co girders how.

Pressure treated glulam beam 3 actual thickness when making a selection below to narrow your results down each selection made will reload the page to display the desired results.

Your company is comparing a simply supported laminated 16 deep wood i beam supplied by georgia pacific and an 8 steel i beam.

Central point load neglecting all other loads to the beam and a maximum allowable deflection of 0 55 what is the maximum distance between supports for each beam type.

Figure 3 shows the zones of a uniformly loaded simply supported beam where the field drilling of holes may be considered.

The equivalent glulam member shown can support the same or greater applied loads than the beam being replaced.

Planks glued together to form a section 6 in.

These non critical zones are located in portions of the beam stressed to less.